Tea Juice Production Line

Other recommendations

Key attributes

Industry-specific attributes

500-10000L

Other attributes

10000 KG

Automatic

Fruit & Vegetable juicer machine, Food Sterilizer, Pasteurizer, Dairy Processing Machines, Emulsifier

VINCE

VINCE

Based on actual data

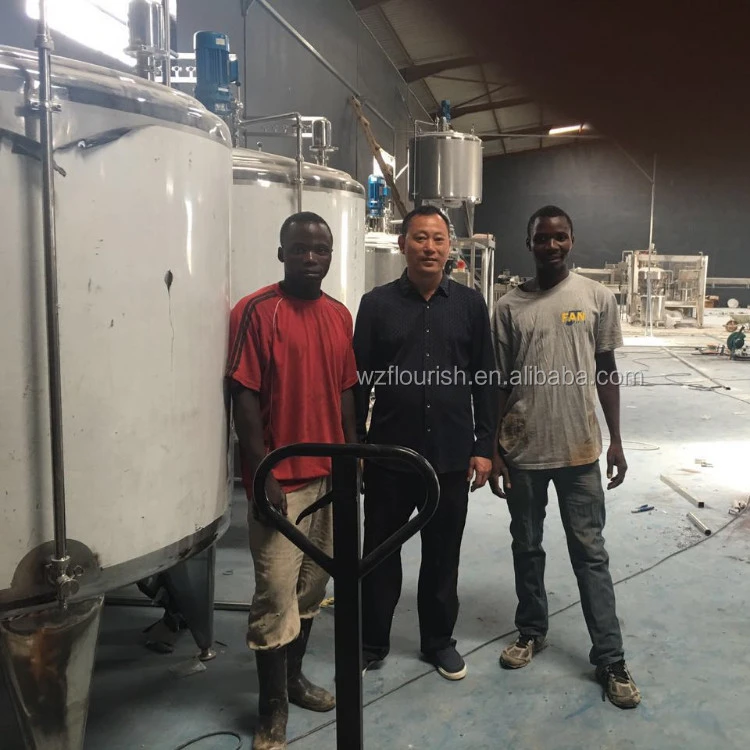

Zhejiang, China

380V/50HZ,3P/ customized

Chocolate, Fruit

stainless steel304/316

500-10000LPH

Packaging and delivery

easy-packing/wooden case packing

Shanghai port/ Ningbo port

Single item

5 Set/Sets per Month

Overview

Tea Juice Production Line

Specifications

Suitable for the material of grape, apple, pear, blueberry, blackberry, strawberry, and other juice manufacturing.

Juice production line

1. Products overview:

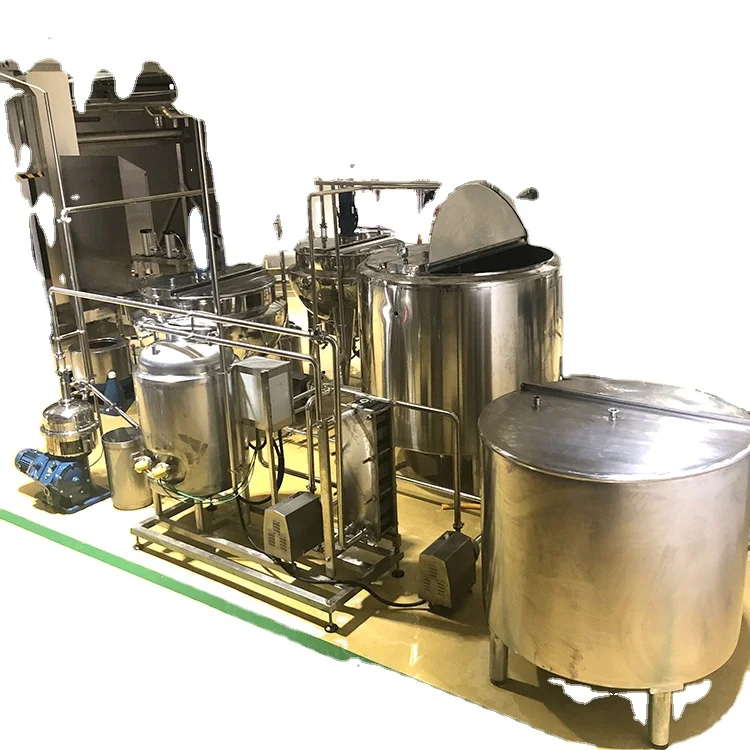

Juice uses all kinds of fruits as raw material, this production line includes working processes of picking, cleaning, crushing, separation, heating, cooling, juice, fermentation, aging, blending, membrane filtering, filling and sealing, sterilization, cooling etc. And it has passed the strict fruit pretreatment process, using the advanced technology of clarified juice vaccination low temperature fermentation method. The products have bright color, pure taste and rich aroma. And it also avoid the disadvantage of traditional process that color and luster of browning that puree (pulp, skins and seeds) inoculated fermentation brings. This process is suitable for the material of grape, apple, pear, blueberry, blackberry, strawberry, pomegranate, orange, mulberry, banana, litchi, longan and other juice wines’ manufacturing. The product not only has the advantages of low wine degree, but also keeps the original nutrients and flavor of the fruits. And it fits the needs of the current people drinking health concept.

2.Technological process

Raw material→ Feeding → Selecting→ Cleaning→ Peduncle desteming and pulp crushing→ Juice extracting→ Seed separator→ Heating and cooling→ Juicing→ Filling →Seal-capping →Sterilization→ Cooling→ Code spurting→ Labeling→ Finished Product

- Tel:

-

Email:

Certifications

SUBSCRIBE

INQUIRY