Stainless Steel Jam Cooking Kettle

Other recommendations

Customization

Customized logo

Min. order: 5

Customized packaging

Min. order: 5

Graphic customization

Min. order: 5

Overview

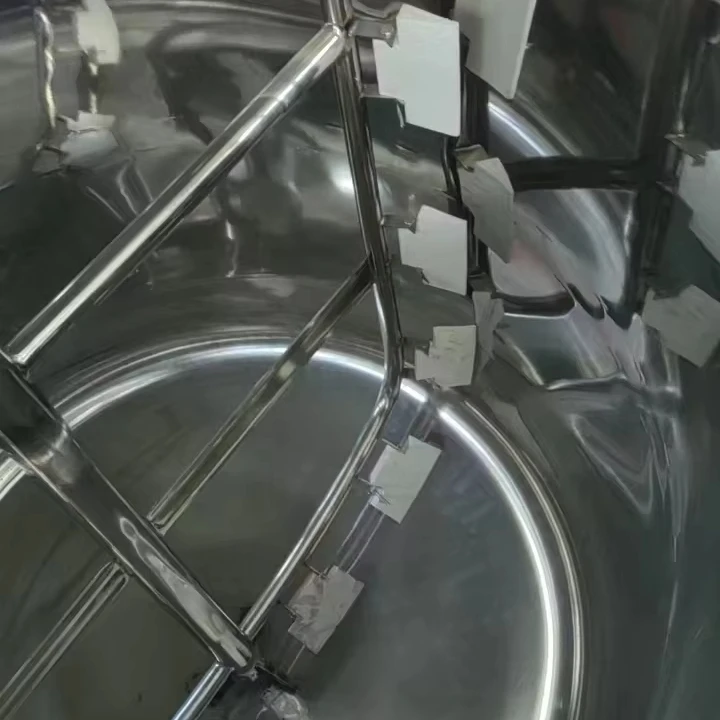

Stainless Steel Jam Cooking Kettle

Specifications

1.Manufacturer(favorable price and high quality) 2.Tilting and Vertical (Agitating) 3.Electric, Steam,Gas

Jacketed Kettle is also named double-layer cauldron. Usually composed of pot and hold feet, and the pot is the double layer structure formed by inside and outside spherical pot; middle layer can add steam to steam. It has characteristics such as big heating area, high thermal efficiency, uniform heating, short boiling time, easy control of the heating temperature etc. Not only has good-appearance, but also easy to install and operate. It is safe and convenient. Now it has been widely applied in food processing. Some large restaurants and canteens also use it to boil soup, cook, stew and porridge. It is considered to be the ideal equipment in the area of improving quality, shortening the time and improving working conditions

Classification of Jacketed Kettle

1. According to Structure: there are Tilting Jacketed Kettle and Vertical Jacketed Kettle

2. According to Heating: there are Electric Heating Jacketed Kettle, Steam Heating Jacketed Kettle and Gas Heating Jacketed Kettle

3. According to Process Need: there are Jacketed Kettle with Agitating and Ones without Agitating

Structure of Jacketed Kettle

Tilting Jacketed Kettle is mainly composed of pot and tilting frame; and the pot is the double layer structure formed by inside and outside spherical pot; middle layer can add steam to heat.

Material

a) Stainless steel inner pot(SUS304/SUS316L), carbon steel outer pot (Q235-B) treated with anti-rust paint

b) The whole machine is made of stainless steel ( SUS304/SUS316L)

Usages of Jacketed Kettle

1. Be widely applied in food processing such as candy, medicine, dairy, alcohol, cake, sweetmeat, beverage, can, etc.

2. Can be used to boil soup, cook, stew and porridge in some large restaurants and canteens. It is considered to be the ideal equipment in the area of improving quality, shortening the time and improving working conditions.

Characteristics of Jacketed Kettle

1. Efficient Heating

Steam heating jacketed kettle takes a certain pressure of steam as heat source. It has characteristics such as big heating area, uniform heating, high thermal efficiency, short boiling time, easy control of the heating temperature etc.

2. Safety and Convenience

Steam heating jacketed kettle adopts stainless steel 304 as production material, which is resistant to heat and acid. The machine is equipped with pressure gauge, safety valve or electrical control box. Not only has good-appearance, but also easy to install and operate. It is safe and convenient.

Technical parameters of Jacketed Kettle

|

Model |

50 |

100 |

200 |

300 |

400 |

500 |

600 |

800 |

1000 |

|

|

Caliber(mm) |

Φ600 |

Φ700 |

Φ800 |

Φ900 |

Φ1000 |

Φ1100 |

Φ1200 |

Φ1400 |

Φ1500 |

|

|

Depth of Pot(mm) |

400 |

450 |

530 |

630 |

680 |

730 |

780 |

830 |

900 |

|

|

Heating area(m2) |

0.45 |

0.58 |

1.12 |

1.42 |

1.75 |

2 |

2.3 |

3.2 |

3.9 |

|

|

Boiling time(min) |

5 |

8 |

11 |

14 |

18 |

22 |

25 |

34 |

40 |

|

|

Interface size |

Steam pipe |

3/4” |

1” |

2” |

||||||

|

Condensate pipe |

3/4” |

1” |

||||||||

|

Working pressure |

≤0.09Mpa(can be adapted according to customers’ requirement) |

|||||||||

|

Stirring speed |

36 r/min(can be adapted according to customers’ requirement) |

|||||||||

|

Stirring power(Kw) |

0.55 |

0.55 |

0.75 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

|

Notes:

1. The stirring power in the chart is standard configuration. Any specific requirements, please let us know.

2. Working pressure in the middle layer ≤0.09Mpa, also, this can be adapted according to customers’ requirement.

3. The process parameters that need provided when choosing the Jacketed Kettle: the nature of material, working pressure, temperature, specific requirements, etc.

- Tel:

-

Email:

Certifications

SUBSCRIBE

INQUIRY