High Quality Stainless Steel Juice Mixing Tank With Agitator

Other recommendations

Key attributes

Industry-specific attributes

100-20000

50000 L

Other attributes

Agitator

Food, juice, milk, powder

1000 KG

New

Zhejiang, China

6 kW

1 Year

Easy to Operate

Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Food Shop, Food & Beverage Shops, Advertising Company

Egypt, Nigeria, Malaysia

New Product 2020

Provided

Provided

1 Year

Motor, Gear, Pump, Bearing

36 - 2840 r.p.m

50000L

SUS304, SUS304L, SUS316, SUS316L

Detergent Powder

Liquid with Suspended Solids

Granulating

VINCE

380V/50HZ or customized

Based on actual size

stainless steel304/316

1year

0.55-15KW

Packaging and delivery

easy-packing

Shanghai port/ Ningbo port

Single item

50 Unit/Units per Month

Customization

Customized logo

Min. order: 1

Customized packaging

Min. order: 1

Graphic customization

Min. order: 1

Overview

Video Description

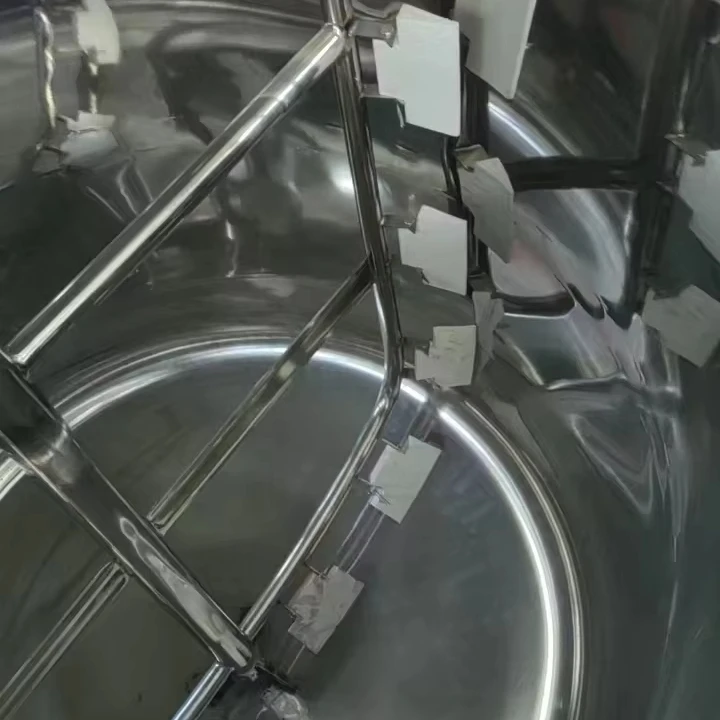

High Quality Stainless Steel Liquid Mixing Tank

Introduction:

Used as mixing tank, blending tank etc.

Ideal in fields such as foods, dairy products, fruit juice beverages, food industry, etc.

Structure characteristics:

Made of single-layer/double layers, three layers stainless steel structure.

Materials are all sanitary stainless steel 304 or 316L.

Humanized structure design and easy to operate.Transition area of interior wall on tank adopts arc for transition to ensure no dead comer of sanitation.

Configuration of tank:

Quick open manhole.

Various types of CIP cleaners.

Fly and insect resistant sanitary breathing cover.

Adjustable triangular bracket.

Dismountable materials input pipe assembly

Thermometer (According to customer requirements ).

Ladder (According to customer requirements).

Paddle blender.

Liquid level meter and lever controller (According to customer requirements).

Eddy-proof board.

Customized and Non-standard products also welcomed.

Features:

1.Usually it has jacket or coiler pipe for cooling/heating

2.The wetted part material can be enamel, C.S., S.S or non-metal material

3.Surface treatment: acid-dipping, polishing, corrosion resistant coating

4.With lifting lugs or supporting legs

5.Custom-made design is available

Technical parameters as follows:

| Work Volume | Dimension of tank | Total height | Insulated layer | Diameter of inlet&outlet |

| (L) | (mmxmm) | (mm) | (mm) | (mm) |

| 500 | 840*1000 | 2300 | 60 | 38 |

| 600 | 920*1000 | 2400 | 60 | 38 |

| 700 | 990*1000 | 2400 | 60 | 38 |

| 800 | 950*1220 | 2550 | 60 | 38 |

| 900 | 1010*1220 | 2700 | 60 | 38 |

| 1000 | 1060*1220 | 2700 | 60 | 51 |

| 2000 | 1340*1500 | 2750 | 60 | 51 |

| 3000 | 1410*2000 | 3500 | 60 | 51 |

| 5000 | 1910*2000 | 3850 | 60 | 51 |

| 10000 | 2300*2440 | 4500 | 60 | 51 |

| 15000 | 2530*3000 | 5200 | 60 | 51 |

| 20000 | 2640*3660 | 5800 | 60 | 51 |

Customized service:

1.We can design the machines according your requirements(materil,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

2. We can offer free technical support and consultation such as design your factory,draw the factory layout and so on.

After-sales service:

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional after service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they canoperate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty with spare parts free.

- Tel:

-

Email:

Certifications

SUBSCRIBE

INQUIRY